Upgrade your fluid transfer system with our top-of-the-line Pipeline Pump. Designed for optimal performance and reliability, it offers seamless and efficient fluid transfer in a variety of industrial applications.

Pipeline Pumps: Powering Fluid Transportation and Distribution

Introduction:

Pipeline pumps play a crucial role in the transportation and distribution of fluids across vast networks of pipelines. In this article, we will delve into the workings, types, and significance of pipeline pumps in various industries and sectors.

Understanding Pipeline Pumps:

Pipeline pumps are specifically designed to facilitate the movement of fluids, such as water, oil, gas, or chemicals, through pipelines. These pumps generate the necessary pressure to overcome frictional losses and deliver the fluids to their intended destinations.

Types of Pipeline Pumps:

a. Centrifugal Pumps: Centrifugal pumps are widely used in pipeline systems due to their efficiency and versatility. They work by converting rotational energy from an impeller into kinetic energy, propelling the fluid through the pipeline.

b. Positive Displacement Pumps: Positive displacement pumps operate by trapping and displacing a fixed volume of fluid with each stroke or rotation. They are suitable for applications requiring high-pressure or viscous fluid transport.

Applications of Pipeline Pumps:

a. Oil and Gas Industry: Pipeline pumps are vital for transporting crude oil, refined petroleum products, and natural gas over long distances. They maintain the necessary flow and pressure levels for efficient distribution.

b. Water Supply and Treatment: Pipeline pumps play a crucial role in water supply systems, ensuring the reliable delivery of clean water to communities, industries, and agricultural areas.

c. Chemical Processing: Pipeline pumps are utilized in chemical plants to transport various chemicals between different process units, ensuring a smooth and controlled flow.

d. Mining and Slurry Transport: Pipeline pumps handle the transportation of slurries, including mining tailings, ores, and other abrasive materials, with their robust construction and ability to handle high-solids content.

Key Considerations:

a. Pump Efficiency: Selecting efficient pipeline pumps helps minimize energy consumption and operating costs.

b. Maintenance and Reliability: Regular maintenance, monitoring, and adherence to manufacturer guidelines are essential for optimal performance and extended pump life.

c. Safety Measures: Proper safety protocols, including pressure monitoring, leak detection, and emergency shutdown systems, are crucial for safe pipeline operations.

Advancements and Future Trends:

Pipeline pump technology continues to evolve, with the integration of smart monitoring systems, remote control capabilities, and energy-saving features. These advancements aim to enhance pump performance, reliability, and overall system efficiency.

Conclusion:

Pipeline pumps are the backbone of fluid transportation and distribution systems, enabling the efficient movement of various fluids across vast distances. Their reliability, efficiency, and application versatility make them indispensable in industries such as oil and gas, water supply, chemical processing, and mining.

Pipeline Pumps: Powering Fluid Transportation and Distribution

Introduction:

Pipeline pumps play a crucial role in the transportation and distribution of fluids across vast networks of pipelines. In this article, we will delve into the workings, types, and significance of pipeline pumps in various industries and sectors.

Understanding Pipeline Pumps:

Pipeline pumps are specifically designed to facilitate the movement of fluids, such as water, oil, gas, or chemicals, through pipelines. These pumps generate the necessary pressure to overcome frictional losses and deliver the fluids to their intended destinations.

Types of Pipeline Pumps:

a. Centrifugal Pumps: Centrifugal pumps are widely used in pipeline systems due to their efficiency and versatility. They work by converting rotational energy from an impeller into kinetic energy, propelling the fluid through the pipeline.

b. Positive Displacement Pumps: Positive displacement pumps operate by trapping and displacing a fixed volume of fluid with each stroke or rotation. They are suitable for applications requiring high-pressure or viscous fluid transport.

Applications of Pipeline Pumps:

a. Oil and Gas Industry: Pipeline pumps are vital for transporting crude oil, refined petroleum products, and natural gas over long distances. They maintain the necessary flow and pressure levels for efficient distribution.

b. Water Supply and Treatment: Pipeline pumps play a crucial role in water supply systems, ensuring the reliable delivery of clean water to communities, industries, and agricultural areas.

c. Chemical Processing: Pipeline pumps are utilized in chemical plants to transport various chemicals between different process units, ensuring a smooth and controlled flow.

d. Mining and Slurry Transport: Pipeline pumps handle the transportation of slurries, including mining tailings, ores, and other abrasive materials, with their robust construction and ability to handle high-solids content.

Key Considerations:

a. Pump Efficiency: Selecting efficient pipeline pumps helps minimize energy consumption and operating costs.

b. Maintenance and Reliability: Regular maintenance, monitoring, and adherence to manufacturer guidelines are essential for optimal performance and extended pump life.

c. Safety Measures: Proper safety protocols, including pressure monitoring, leak detection, and emergency shutdown systems, are crucial for safe pipeline operations.

Advancements and Future Trends:

Pipeline pump technology continues to evolve, with the integration of smart monitoring systems, remote control capabilities, and energy-saving features. These advancements aim to enhance pump performance, reliability, and overall system efficiency.

Conclusion:

Pipeline pumps are the backbone of fluid transportation and distribution systems, enabling the efficient movement of various fluids across vast distances. Their reliability, efficiency, and application versatility make them indispensable in industries such as oil and gas, water supply, chemical processing, and mining.

Why Choose Us?

The pump has compact structure, small volume and small installation area. Stable operation, low power consumption, convenient decoration.According to the request flow and head, pumps can install in series or in parallel to adjust the flow and head.

The water pump is suitable for urban environmental protection, greenhouse sprinkler irrigation, construction, mining, equipment cooling, etc.Save floor space,Easy to dissemble and maintain,Various installations,Easy to installation,Stable operation,Low noise。

English

English عربى

عربى

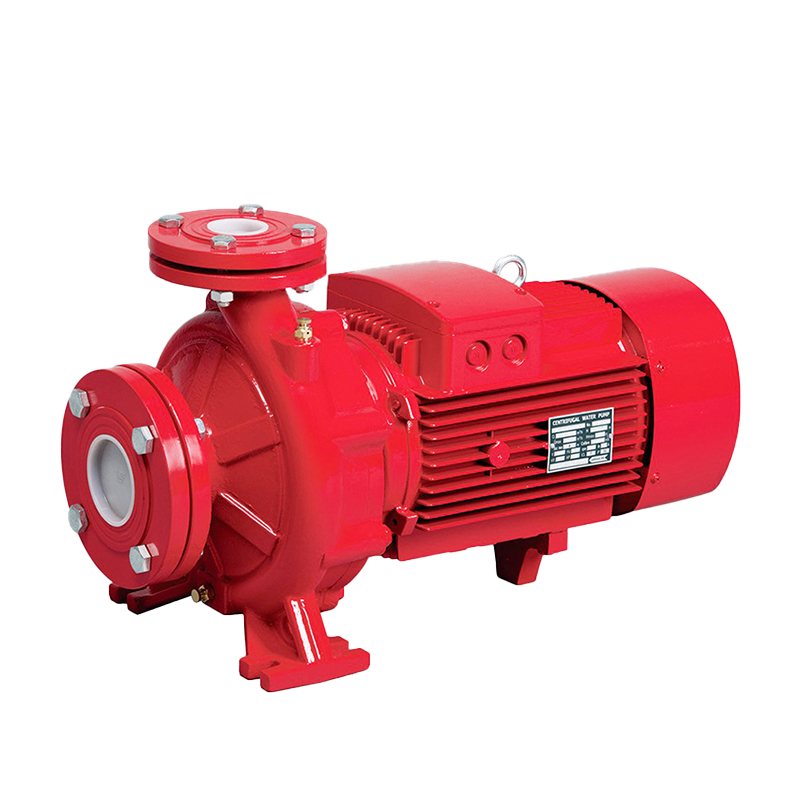

Fire Pump and System

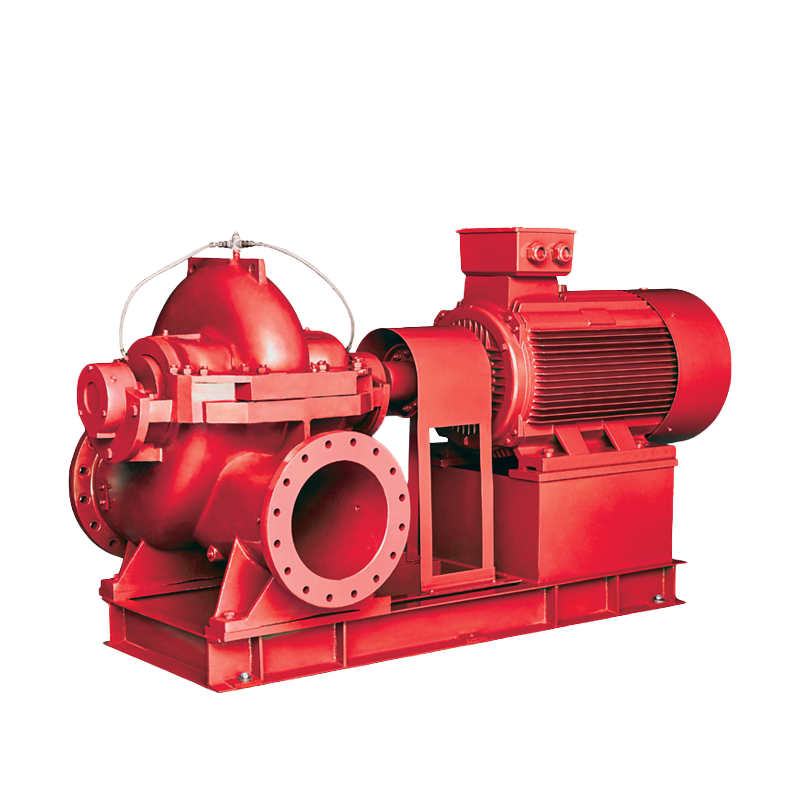

Fire Pump and System Split Case Pump

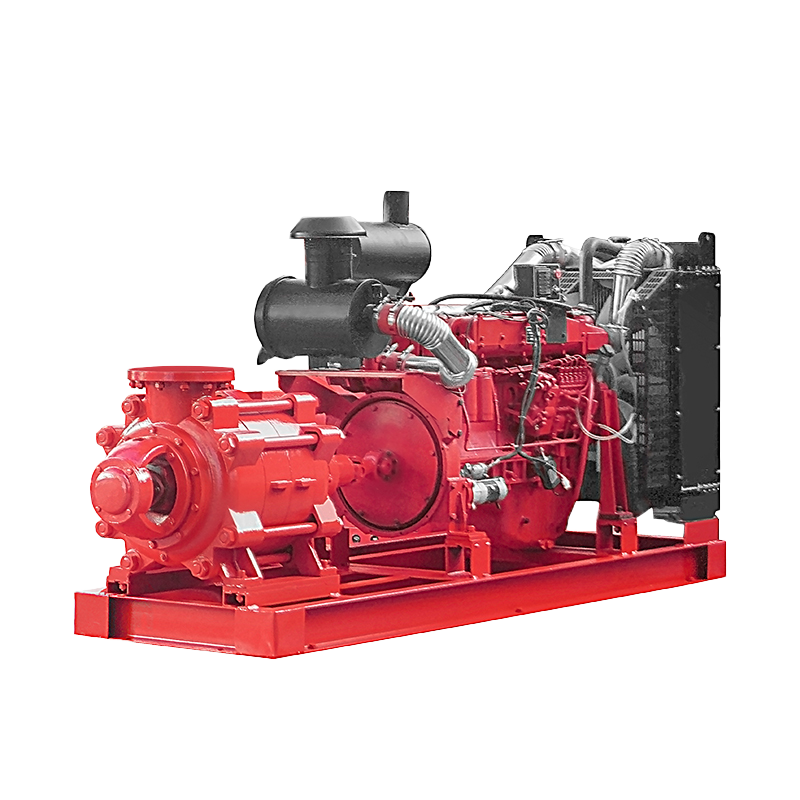

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

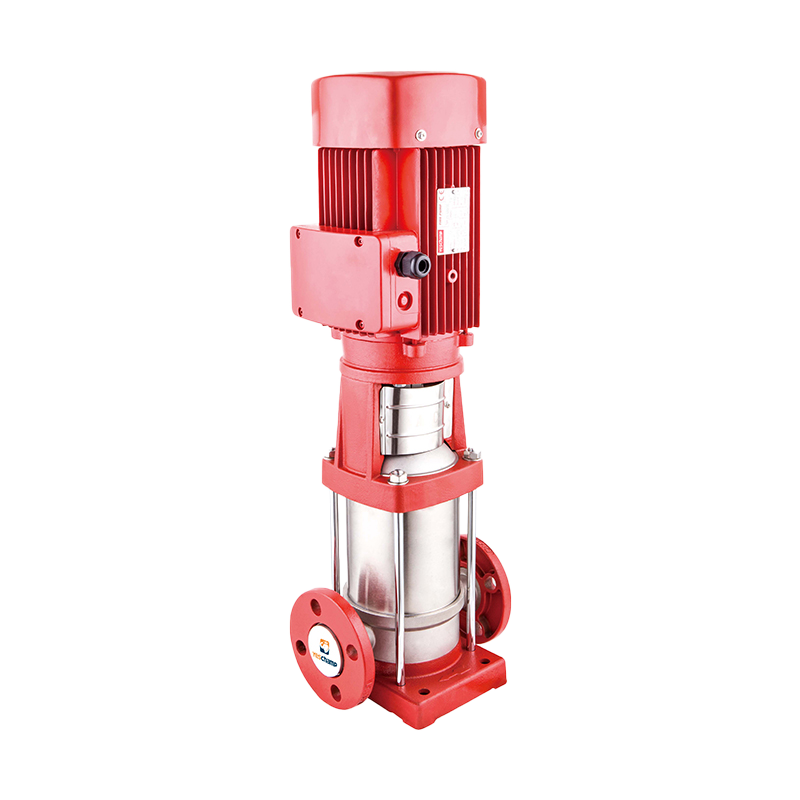

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

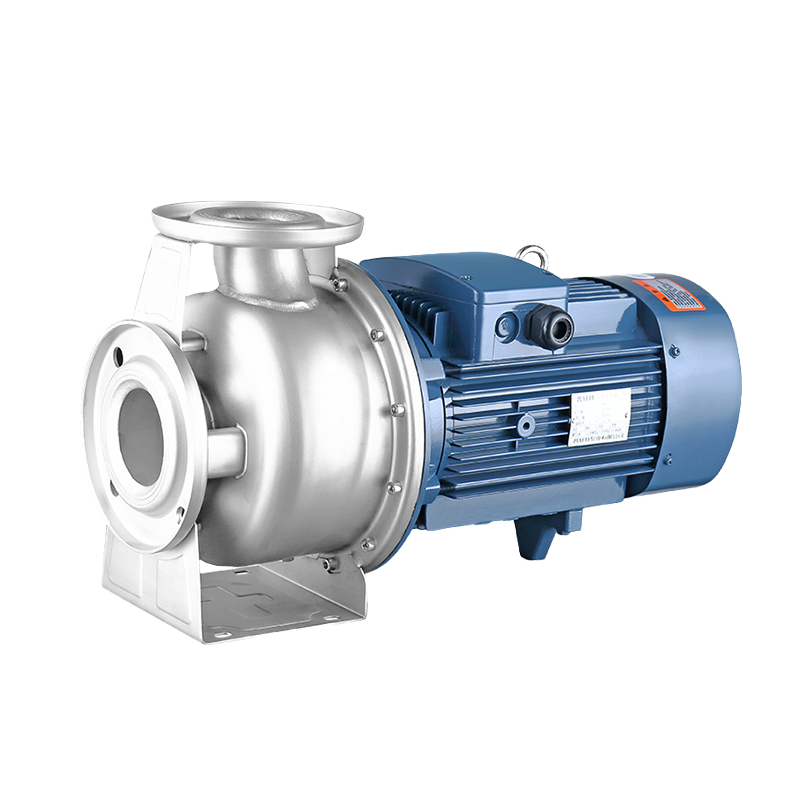

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump